Als u nog steeds vertrouwt op handmatige of verouderde buigmethoden, dan moet u in de huidige veeleisende productie om concurrerend te blijven, elk aspect van uw fabricageproces optimaliseren.U heeft waarschijnlijk problemenEen van de belangrijkste factoren in de ontwikkeling van de moderne metaalfabricage is deCNC-persrem.

Maar is een CNC Press Brake echt nodig voor uw winkel? Het antwoord, voor de meeste bedrijven die willen gedijen, is een klinkend ja.We zullen de 5 belangrijkste redenen bespreken waarom investeren in een CNC-persrem niet alleen een goed idee is, maar ook een strategische stap is om uw productie te verhogen., winstgevendheid en productkwaliteit.

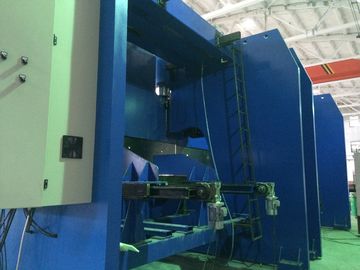

Voordelen van CNC-persremmen

CNC (Computer Numerical Control) -persremmen bieden aanzienlijke voordelen ten opzichte van traditionele handmatige of mechanische persremmen.Het maakt ze de voorkeur keuze voor de moderne productie en plaat gebogen operatiesHier zijn enkele van de belangrijkste voordelen:

1.Nauwkeurigheid en nauwkeurigheid

CNC-persremmen zijn ontworpen voor hoge precisie. Het CNC-systeem zorgt voor geautomatiseerde controle van het buigingsproces, zodat elke buiging met een hoge mate van nauwkeurigheid wordt uitgevoerd.zelfs voor complexe geometrieën en strakke tolerantiesDe mogelijkheid om exacte buighoeken en parameters in te voeren en op te slaan, zorgt voor consistentie tussen meerdere onderdelen, waardoor het risico op menselijke fouten wordt verminderd.

-

Verbeterde kwaliteit van onderdelen: Elk onderdeel heeft identieke bochten, cruciaal voor toepassingen die een constante precisie vereisen, zoals de luchtvaart, de automobielindustrie en de elektronische industrie.

2.Verhoogde productiviteit

Met CNC-persremmen wordt de tijd die nodig is om een taak in te stellen en af te ronden aanzienlijk verkort in vergelijking met handmatige methoden.en snelle heen en weer bewegingen resulteren in snellere cyclustijden.

3.Complexe buigvermogen

CNC-persremmen kunnen complexere buigwerkzaamheden uitvoeren die met traditionele persremmen moeilijk of onmogelijk te verwezenlijken zijn.waar het materiaal tegelijkertijd langs meer dan één as kan worden gebogen, evenals het verwerken van meerdere hoeken en straal in één operatie.

4.Verkorte instellingstijd

CNC-persremmen kunnen vooraf geprogrammeerde buigsequenties opslaan, waardoor het gemakkelijker is om tussen verschillende banen te schakelen zonder uitgebreide heruitrusting.Dit vermindert de instellingstijd voor elke productie, het verhogen van de operationele efficiëntie.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!